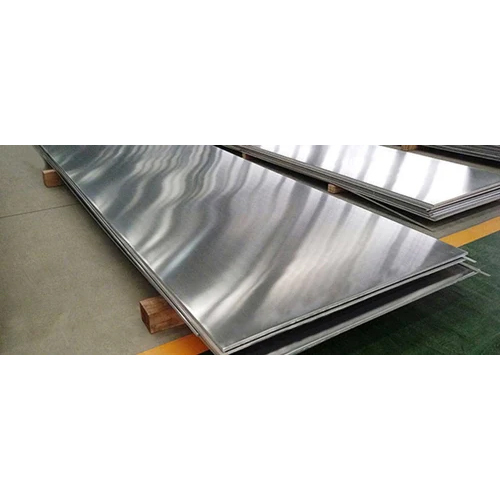

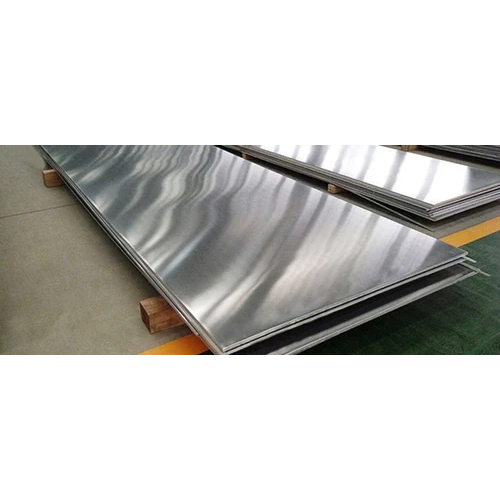

Inconel 625 Sheet

Inconel 625 Sheet Specification

- Corrosion Resistant

- Excellent

- Recyclable

- Yes

- Heat Resistance

- Yes

- Material Composition %

- Ni 58%, Cr 20-23%, Mo 8-10%, Nb+Ta 3.15-4.15%, Fe 5%

- Product Form

- Flat Sheet / Plate

- Coating Type

- Uncoated / As per requirement

- Diameter

- N/A (Sheet Product)

- Hardness

- Rockwell B95 max

- Size

- 1000mm x 2000mm, 1250mm x 2500mm, 1500mm x 3000mm or as required

- Tensile Strength

- 830 MPa min

- Product Name

- Inconel 625 Sheet

- Steel Type

- Nickel Alloy

- Steel Product Type

- Sheet

- Grade

- Inconel 625

- Thickness

- 0.5 mm to 50 mm

- Shape

- Rectangular / Plate Sheet

- Steel Standard

- ASTM B443 / ASME SB443

- Surface

- Polished / Bright / Hot Rolled / Cold Rolled

- Composition

- Nickel-Chromium-Molybdenum-Niobium Alloy

- Application

- Aerospace, Chemical Processing, Marine, Power Generation, Oil & Gas

- Dimension (L*W*H)

- Custom sizes available

- Weight

- As per size and thickness

- Color

- Silver / Metallic

- Material Grade

- Alloy 625

- Finish Type

- 2B / BA / No.1 / Custom

- Usage

- High strength & corrosion environments

- Formability

- Excellent

- Magnetic Properties

- Non-magnetic

- Conductivity

- Low (Ni-base alloy concern)

- Weldability

- Excellent (GTAW, GMAW, SMAW, resistance welding)

- Density

- 8.44 g/cm

- Machinability

- Moderate

- Edge Type

- Mill Edge / Slit Edge / Sheared

- Delivery Condition

- Annealed / Solution Annealed

- Stock Availability

- Ready stock or made to order

- Minimum Order Quantity

- As per requirement

- Melting Point

- 12901350C

- Elongation at Break

- 30% min

Inconel 625 Sheet Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 10-15 Days

About Inconel 625 Sheet

Advanced Applications & Use Methods

Inconel 625 Sheet is widely used in high-strength and corrosive environments, doubling as both a forming material and a structural component. Its use type spans aerospace parts, marine hardware, chemical processing equipment, and power generation. Generally integrated through welding or fabrication methods, this nickel alloy sheet adapts seamlessly to custom dimensions and complex designs, ensuring longevity and superior operational reliability in harsh settings.

Sample Availability & Efficient Dispatch

Request a sample of the Inconel 625 Sheet to evaluate its properties firsthand. Our streamlined dispatching process ensures timely shipment, whether for single samples or bulk orders. We offer sturdy packaging to safeguard quality during freight, with delivery timeframes tailored to order volumes and requirements. Packaging and freight charges are competitively structured, maximizing value on each dispatched batch and ensuring your product arrives in pristine condition, ready for immediate application.

FAQ's of Inconel 625 Sheet:

Q: How is Inconel 625 Sheet typically used in industrial applications?

A: Inconel 625 Sheet is commonly used as a structural or protective material in industries such as aerospace, marine, chemical processing, oil and gas, and power generation due to its high strength, excellent corrosion resistance, and heat tolerance.Q: What is the usual process for ordering and customizing Inconel 625 Sheets?

A: Customers can choose from ready stock or specify custom sizes and finishes. Submit your requirements, including thickness, dimensions, and finish type, and the manufacturer will fabricate and dispatch tailored sheets accordingly.Q: When can I expect delivery after placing an order for Inconel 625 Sheet?

A: Delivery times depend on stock availability and order quantity. Ready stock is dispatched quickly, while made-to-order sheets are shipped after production, typically within agreed timelines discussed during ordering.Q: Where is Inconel 625 Sheet manufactured and supplied from?

A: This product is manufactured, exported, and supplied from India, with a robust network serving both domestic and international markets.Q: What are the main benefits of using Inconel 625 Sheet compared to standard steel sheets?

A: The main advantages include superior heat and corrosion resistance, high tensile strength, and non-magnetic properties, making Inconel 625 ideal for extreme environments where standard steel may fail.

Price 300 INR/ Kilograms

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 10-15 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Products Category

Inconel 718 Sheets

Price 3400 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Weight : Varies with size and thickness

Usage : Aerospace, Power plants, Chemical industries, Marine Engineering

Steel Product Type : Other, Sheet

Steel Standard : Other, ASTM B670, AMS 5596, AMS 5597, ASTM B637

Inconel 625 Tubes

Price 3500 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Weight : Varies with Size and Length

Usage : Condensers, Heat Exchangers, Pressure Vessels, Piping Systems

Steel Product Type : Other, Seamless and Welded Tubes

Steel Standard : Other, ASTM B444, ASTM B704, ASTM B705

Inconel 600 Filler Wire

Price 3200 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Weight : Varies as per spool; commonly available weights are 5kg, 10kg, and 15kg

Usage : Suitable for GTAW (TIG) and GMAW (MIG) welding

Steel Product Type : Other, Filler Wire

Steel Standard : Other, ASTM B166

Inconel 800 Sheets

Price 3600 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Weight : Varies as per dimension and thickness

Usage : Industrial, Hightemperature, Corrosive environment applications

Steel Product Type : Other, Sheet

Steel Standard : ASTM B409 / ASME SB409, Other

GST : 27AAPPS5635Q1ZM

|

PRAGATI METAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese