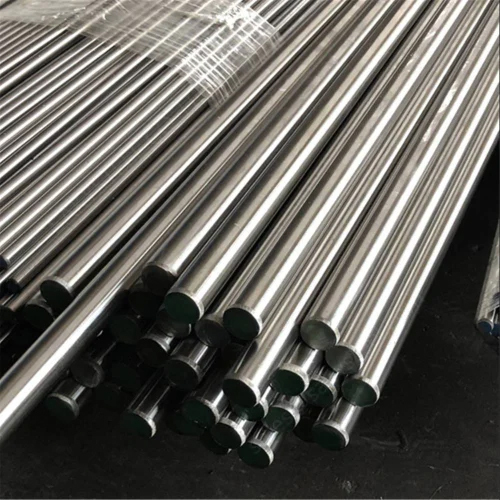

Inconel 800 Tube

Inconel 800 Tube Specification

- Heat Resistance

- Yes

- Diameter

- 6 mm to 219 mm OD

- Product Form

- Tube

- Recyclable

- Yes

- Tensile Strength

- 600 MPa min

- Coating Type

- Uncoated

- Corrosion Resistant

- Excellent, especially to oxidation and carburization

- Hardness

- 160-220 HB

- Size

- Standard and custom sizes

- Material Composition %

- Ni: 30-35%, Cr: 19-23%, Fe: Balance

- Product Name

- Inconel 800 Tube

- Steel Type

- Nickel-Chromium Alloy

- Steel Product Type

- Seamless/ Welded Tube

- Grade

- Inconel 800 (UNS N08800)

- Thickness

- Available from 0.5 mm to 10 mm

- Shape

- Round

- Steel Standard

- ASTM B163, ASTM B407

- Surface

- Bright / Annealed / Polished

- Composition

- Nickel, Iron, Chromium alloy

- Application

- Heat exchangers, chemical processing, nuclear steam generator tubing, power generation, petrochemical industry

- Dimension (L*W*H)

- Custom as per requirement

- Weight

- Varies with size and length

- Color

- Metallic silver

- Material Grade

- Inconel 800

- Finish Type

- Smooth / Polished

- Usage

- Industrial, Chemical, Power Plants, Refineries

- Density

- 7.94 g/cm

- Melting Point

- 13571385C

- Ends

- Plain End / Beveled End / Threaded

- Proof Stress (0.2% offset)

- 300 MPa min

- Elongation

- 30% min

- Packaging Type

- Wooden Boxes, Bundled with Plastic Wrapping

- Standards/Certification

- ISO, ASTM, NACE, PED

- Manufacturing Process

- Seamless and Welded

- Length

- Single Random, Double Random, or Custom Cut

- Delivery Condition

- Annealed & Pickled

Inconel 800 Tube Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 10-15 Days

About Inconel 800 Tube

Inconel 800 Tube: Application Method & Areas

Inconel 800 Tubes are applied using welded or seamless techniques, ensuring optimal integration into both new and existing systems. Used extensively in heat exchangers, nuclear steam generators, and chemical processing, these tubes thrive where high strength and resistance to oxidation are critical. Key application areas include industrial facilities, power plants, petrochemical refineries, and the chemical sector. Their customizability in dimensions and outstanding elongation make them a top solution for demanding operational requirements.

Certifications, Packaging, and Delivery of Inconel 800 Tubes

Inconel 800 Tubes are certified to international benchmarks including ISO, ASTM, NACE, and PED, adding remarkable valuation and credibility to your projects. FOB ports include major terminals in India, facilitating timely global shipments. Tubes are packaged securely in wooden boxes or bundled with plastic wrapping for maximum protection. Delivered in annealed and pickled condition, the usual delivery timeframe aligns with order specifications and destination-with quality and safety as top priorities during every step.

FAQ's of Inconel 800 Tube:

Q: How are Inconel 800 Tubes manufactured?

A: Inconel 800 Tubes are produced using seamless and welded methods, utilizing a nickel-chromium alloy in strict accordance with ASTM and ISO standards.Q: What are the primary applications of Inconel 800 Tubes?

A: These tubes are widely used in heat exchangers, chemical processing plants, nuclear steam generator tubing, power generation, and petrochemical industries because of their outstanding resistance to heat and corrosion.Q: When can I expect delivery after placing an order for Inconel 800 Tubes?

A: Delivery times vary depending on quantity and customization, but shipments typically follow prompt processing and are dispatched from leading FOB ports in India, as per your specified schedule.Q: Where are Inconel 800 Tubes most effective?

A: They excel in environments exposed to high temperatures and corrosive elements, such as power plants, refineries, and chemical processing units.Q: What benefits do Inconel 800 Tubes offer in industrial usage?

A: These tubes offer outstanding proof stress, tensile strength, corrosion resistance, and heat resistance-making them ideal for demanding industrial conditions and ensuring long-lasting performance.Q: How are Inconel 800 Tubes packaged for delivery?

A: For optimal safety, tubes are packaged in sturdy wooden boxes or bundled with protective plastic wrapping to prevent damage during transit.

Price 3000 INR/ Kilograms

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 10-15 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Products Category

Inconel 800 Sheets

Price 3600 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Corrosion Resistant : Excellent

Steel Standard : ASTM B409 / ASME SB409, Other

Application : Other, Chemical processing, petrochemical, power generation, furnace components, heat exchangers

Weight : Varies as per dimension and thickness

Inconel 718 Sheets

Price 3400 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Corrosion Resistant : Excellent

Steel Standard : Other, ASTM B670, AMS 5596, AMS 5597, ASTM B637

Application : Other, Aerospace, Chemical Processing, Gas Turbine Components, Nuclear Engineering, Marine, Oil & Gas, Power Generation, Cryogenic Storage, Fasteners

Weight : Varies with size and thickness

Inconel 625 Tubes

Price 3500 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Corrosion Resistant : Excellent Resistance to Pitting, Crevice and Intergranular Corrosion

Steel Standard : Other, ASTM B444, ASTM B704, ASTM B705

Application : Other, Chemical Processing, Aerospace, Marine, Nuclear Reactors, Power Generation, Oil and Gas Industries

Weight : Varies with Size and Length

Inconel 800 Filler Wire

Price 3300 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Corrosion Resistant : Excellent resistance to oxidation and carburization in hightemperature environments

Steel Standard : Other, ASTM B166 / ASME SB166

Application : Other, Welding, Joining, and Repair of Alloy 800/800H/800HT, Chemical Processing, Oil and Gas, Power Generation, Petrochemical Industries

Weight : As per spool size or quantity ordered

GST : 27AAPPS5635Q1ZM

|

PRAGATI METAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese