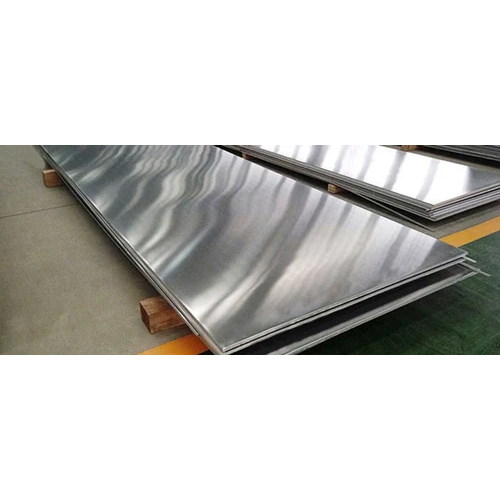

304 Stainless Steel Sheet

Price 100 INR/ Kilograms

304 Stainless Steel Sheet Specification

- Recyclable

- Yes

- Hardness

- HRB 92 (annealed)

- Coating Type

- Uncoated / PVC-Coated on request

- Product Form

- Sheet

- Material Composition %

- Cr 18-20, Ni 8-10.5, C 0.08

- Corrosion Resistant

- Yes, Excellent resistance to corrosion and oxidation

- Diameter

- Not applicable for sheet; applicable for coils/rounds

- Size

- Custom & standard sizes (8 x 4 ft, 10 x 4 ft, etc.)

- Heat Resistance

- Up to 870C (continuous service) / 925C (short periods)

- Tensile Strength

- 515-750 MPa

- Product Name

- 304 Stainless Steel Sheet

- Steel Type

- Stainless Steel

- Steel Product Type

- Sheet

- Grade

- 304

- Thickness

- 0.3 mm - 50 mm

- Shape

- Rectangular / Sheet

- Steel Standard

- ASTM A240 / AISI 304

- Surface

- 2B, BA, No.1, No.4, Mirror, Matt

- Composition

- Cr 18-20%, Ni 8-10.5%, C 0.08%, Mn 2.0%, Si 1.0%, P 0.045%, S 0.03%, Fe balance

- Application

- Used in construction, manufacturing, kitchen equipment, food processing, chemical, oil and gas, and architectural sectors

- Dimension (L*W*H)

- As required (standard sizes: 8ft x 4ft, 10ft x 4ft, customizable)

- Weight

- Varies by thickness and size

- Color

- Silver / Natural

- Material Grade

- SS 304

- Finish Type

- 2B, BA, No.4, Mirror, customized finishes

- Usage

- Structural, fabrication, kitchenware, chemical processing equipment, architectural

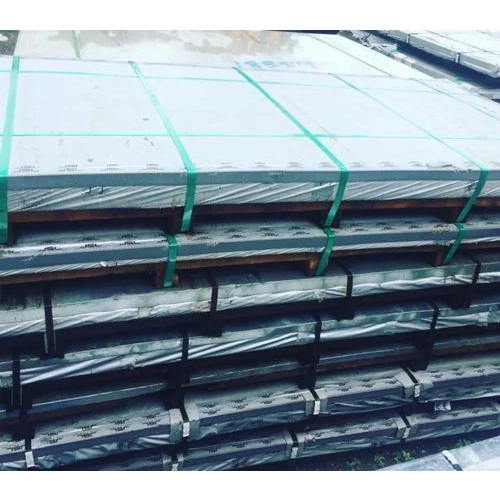

304 Stainless Steel Sheet Trade Information

- Minimum Order Quantity

- 10 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Kilograms Per Day

- Delivery Time

- 3 Days

- Packaging Details

- WOODEN BOX

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- MTC

About 304 Stainless Steel Sheet

We "PRAGATI METAL CORPORATION" are the leadingtrader, wholesaler and exporter of a wide range of 304 Stainless Steel Sheets, 316 Stainless Steel Sheets, 409 Stainless Steel Sheets, 441 Stainless Steel Sheets, etc. Our provided products are manufactured by taking only top grade components at our vendor ultra-modern processing unit. These products are highly demanded by the customers for their accurate dimension, best quality, fine finishing, light weight and longer service life. Apart from this, these offered products are used in various fields.Exceptional Durability and Versatility

304 Stainless Steel Sheet stands out for its strength, formability, and ability to resist corrosion and oxidation, even in demanding environments. It is available in thicknesses from 0.3 mm to 50 mm and can be supplied in standard sizes such as 8ft x 4ft or 10ft x 4ft, with customizable dimensions upon request. This adaptability makes it a suitable choice for diverse applications in construction, manufacturing, and more.

Applications Across Multiple Industries

This stainless steel sheet finds wide usage in construction, kitchen equipment, food processing, chemical plants, oil and gas, and architectural projects. Its excellent weldability, non-magnetic properties in the annealed condition, and attractive finish options (2B, BA, No.4, Mirror, Matt) make it especially favored for both functional and aesthetic purposes.

High-Temperature Resistance & Easy Maintenance

304 Stainless Steel Sheet maintains its structural integrity at elevated temperatures, allowing continuous operation up to 870C. The material also offers ease of maintenance since its smooth surface resists staining and allows for hygienic cleaning, making it ideal for food industry and healthcare environments.

FAQs of 304 Stainless Steel Sheet:

Q: How is the 304 Stainless Steel Sheet typically fabricated or processed?

A: The 304 Stainless Steel Sheet can be readily cut, welded, bent, and formed using standard fabrication methods. Its excellent weldability allows it to be joined by TIG, MIG, spot, and arc welding processes without compromising corrosion resistance.Q: What benefits does using 304 Stainless Steel Sheet offer in construction and manufacturing?

A: The sheets high strength, corrosion resistance, and ease of fabrication make it a preferred material in construction and manufacturing. It provides longevity, reduces maintenance costs, and ensures safety and reliability in structural applications.Q: When should I choose a 304 grade stainless steel sheet over other grades?

A: 304 stainless steel is ideal when you need a cost-effective, corrosion-resistant material with good formability and weldability for use in food processing, architectural features, or chemical equipment. For environments with higher corrosive exposure (like marine applications), grades such as 316 might be more suitable.Q: Where can 304 Stainless Steel Sheets be used most effectively?

A: These sheets perform exceptionally well in environments exposed to moisture, chemicals, and heat. Typical applications include kitchen equipment, food processing plants, building facades, chemical processing equipment, and oil and gas infrastructure.Q: What finishes are available for 304 Stainless Steel Sheet and why choose different ones?

A: Finishes include 2B, BA, No.4, Mirror, and Matt, among others. A smooth 2B finish is ideal for general use, Mirror finish provides a reflective appearance for decorative applications, No.4 offers a brushed look suitable for kitchenware, and Matt gives a subtle, non-reflective surface.Q: How does the non-magnetic property benefit certain applications?

A: In its annealed condition, 304 Stainless Steel Sheet is non-magnetic, which is particularly advantageous in sensitive electronic, medical, or laboratory environments where magnetism can affect instruments or processes.Q: Is 304 Stainless Steel Sheet recyclable and environmentally friendly?

A: Yes, 304 Stainless Steel Sheet is 100% recyclable. Its production and use support sustainable practices by reducing raw material consumption and minimizing environmental impact through recycling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Sheet Category

Jindal Stainless Steel Sheets

Price 200 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : 202, 304, 316 & custom as per requirement

Surface : 2B (Mill finish), BA (Bright Annealed), Mirror, Matt, Hairline

Shape : Other, Rectangular Sheet

Thickness : 0.5 mm to 50 mm

Stainless Steel 202 Coils

Price 140 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : 202

Surface : 2B, BA, No. 1, No. 4, Mirror Finish

Shape : Other, Coil

Thickness : 0.3 mm to 8 mm

50 Mm SS 304 Sheets

Price 150 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : SS 304

Surface : Hot Rolled, Mill Finish

Shape : Other, Rectangular

Thickness : 50 mm

430 S Stainless Steel Sheets

Price 120 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Grade : 430

Surface : 2B, BA, MATTE ,HAIRLINE

Shape : Plate

Thickness : 0.2MM TO 100MM Millimeter (mm)

GST : 27AAPPS5635Q1ZM

|

PRAGATI METAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry