Stainless Steel Bright Bar

Price 200 INR/ Kilograms

MOQ : 100 Kilograms

Stainless Steel Bright Bar Specification

- Material Composition %

- Cr: 16-22%, Ni: 6-14% (approx), Fe: Balance

- Size

- Standard and Custom Sizes available

- Coating Type

- None / Uncoated

- Product Form

- Bar

- Recyclable

- Yes

- Heat Resistance

- Up to 870C (depending on grade)

- Diameter

- 6 mm to 100 mm or as specified

- Corrosion Resistant

- Yes

- Tensile Strength

- 515 - 750 MPa (depending on grade)

- Hardness

- 160 - 250 HB (depending on grade)

- Product Name

- Stainless Steel Bright Bar

- Steel Type

- Stainless Steel

- Steel Product Type

- Bar

- Grade

- 201, 202, 304, 304L, 316, 316L, 410, 420, 430 or as specified

- Thickness

- 6 mm to 100 mm (or as required)

- Shape

- Round, Square, Hexagonal, Flat

- Steel Standard

- ASTM, JIS, DIN, EN, GB, IS

- Surface

- Bright, Polished

- Composition

- Iron, Chromium, Nickel and other alloying elements

- Application

- Automobile, Construction, Engineering, Fabrication, Industrial machinery

- Dimension (L*W*H)

- Customizable / As per requirement

- Weight

- Varies as per Size and Length

- Color

- Silver / Metallic

- Material Grade

- AISI 304, 316, 410, 420, etc.

- Finish Type

- Bright Finish

- Usage

- Machinery Parts, Shafts, Fasteners, Valve & Pump components

Stainless Steel Bright Bar Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 10-15 Days

About Stainless Steel Bright Bar

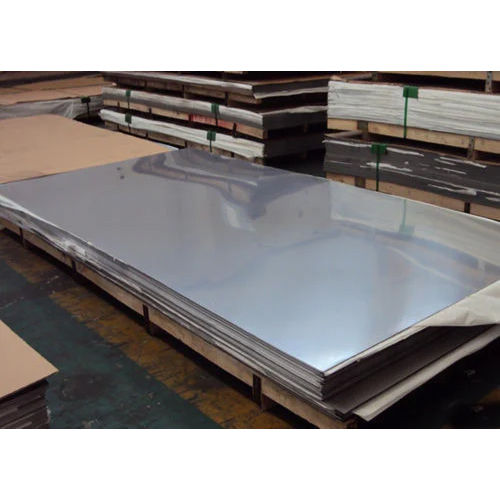

Unlock the potential of your engineering projects with our exquisite Stainless Steel Bright Bars, crafted using the finest cold drawn or centreless ground processes. Available in lengths from 2 to 6 meters-or as required-these noteworthy bars come in a range of grades (201, 304, 316, 410, 420, and more), shapes, and finishes. Choose from round, square, hexagonal, or flat, and procure sharp, radius, or chamfered ends to suit your needs. Customizable dimensions and magnetic properties, robust yield strength, remarkable machinability, corrosion resistance, and ISO 9001:2015 certification ensure optimum performance for automotive, construction, and machinery applications. Pick yours for unmatched durability and superior quality!

Stainless Steel Bright Bar: Key Features and Directions for Use

Select the grade and shape best suited for your project, whether for shafts, fasteners, or valve components. These bars are ideal for industrial machinery, construction, or fabrication, thanks to their high strength and heat resistance up to 870C. Noteworthy features include customized sizes, bright finish, and corrosion resistance. Simply procure the right specification, and utilize for both heavy duty and precise engineering applications, optimizing performance and aesthetics alike.

Domestic and Export Market Reach & Quick Shipment Solutions

Our Stainless Steel Bright Bars are in demand across India's domestic manufacturing clusters, with samples available for quality assurance. Main export markets include the Middle East, Europe, and Southeast Asia. Securely packaged in bundles or wooden boxes, prompt quotations are offered on request. We assure quick dispatch and secure shipping, enabling dependable supply chains for manufacturers, suppliers, and wholesalers seeking reliability and excellence.

Stainless Steel Bright Bar: Key Features and Directions for Use

Select the grade and shape best suited for your project, whether for shafts, fasteners, or valve components. These bars are ideal for industrial machinery, construction, or fabrication, thanks to their high strength and heat resistance up to 870C. Noteworthy features include customized sizes, bright finish, and corrosion resistance. Simply procure the right specification, and utilize for both heavy duty and precise engineering applications, optimizing performance and aesthetics alike.

Domestic and Export Market Reach & Quick Shipment Solutions

Our Stainless Steel Bright Bars are in demand across India's domestic manufacturing clusters, with samples available for quality assurance. Main export markets include the Middle East, Europe, and Southeast Asia. Securely packaged in bundles or wooden boxes, prompt quotations are offered on request. We assure quick dispatch and secure shipping, enabling dependable supply chains for manufacturers, suppliers, and wholesalers seeking reliability and excellence.

FAQ's of Stainless Steel Bright Bar:

Q: How do I choose the right grade of Stainless Steel Bright Bar for my application?

A: Select the grade based on required magnetic properties, corrosion resistance, mechanical strength, and intended use. For non-magnetic applications, 304 is ideal, while 410 or 420 suits magnetic requirements. Consult with our team for tailored recommendations.Q: What is the manufacturing process of these stainless steel bright bars?

A: Our bright bars are manufactured using cold drawn or centreless ground techniques, providing enhanced precision, surface finish, and strength in every bar.Q: Where can these bars be used most effectively?

A: These bars are used in automobile parts, construction frameworks, industrial machinery, and fabrication projects. Their adaptability and strength make them suitable for diverse engineering sectors.Q: When can I expect delivery after placing an order?

A: Lead times depend on order size and specifications. We aim for quick dispatch and timely deliveries, ensuring efficient logistics for both domestic and international shipments.Q: What are the packaging options for safe transportation?

A: Bright Bars are securely packed in bundles or wooden boxes, ensuring protection during transit, whether for domestic supply or international export.Q: Is customization available for size, shape, and finish?

A: Yes, we offer complete customization according to the client's specifications, including dimensions, edges, finishes, and packaging requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Sheet Category

Stainless Steel 202 Coils

Price 140 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Steel Standard : Other, ASTM A240 / A240M

Product Name : Other, Stainless Steel 202 Coils

Surface : 2B, BA, No. 1, No. 4, Mirror Finish

Thickness : 0.3 mm to 8 mm

50 Mm SS 304 Sheets

Price 150 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Steel Standard : Other, ASTM A240 / ASME SA240

Product Name : Other, 50 Mm SS 304 Sheets

Surface : Hot Rolled, Mill Finish

Thickness : 50 mm

430 S Stainless Steel Sheets

Price 120 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Steel Standard : ASTM

Product Name : Steel Products

Surface : 2B, BA, MATTE ,HAIRLINE

Thickness : 0.2MM TO 100MM Millimeter (mm)

PRAGATI METAL CORPORATION

GST : 27AAPPS5635Q1ZM

GST : 27AAPPS5635Q1ZM

15-A/65-73, Habib Building, 2'nd Panjrapole Lane, C.P.Tank Road, Mumbai - 400004, Maharashtra, India

Phone :08045802406

|

PRAGATI METAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry