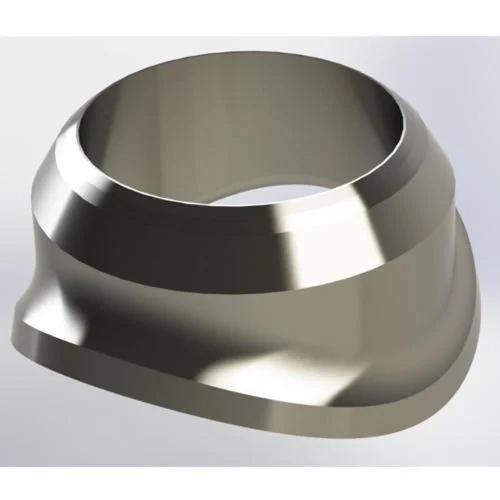

Stainless Steel Sweepolet

Stainless Steel Sweepolet Specification

- Connection

- Welded

- Surface Finish

- Polished

- End Protector

- Plastic Caps

- Type

- Sweepolet

- Tolerance

- 0.1 mm

- Application

- Pipe Branch Connections

- Product Type

- Pipe Fitting

- Material

- Stainless Steel

- Shape

- Elongated Sweep (45 angle)

- Thickness

- Sch 10 to Sch 160 (as per order)

- Technique

- Forged

- Standard

- ASME B16.9 / MSS-SP 97 / ASTM A182

- Alloy or Not

- Alloy

- Outer Diameter

- 1/2 to 24 (DN15DN600)

- Surface Treatment

- Pickled / Passivated

- Length

- Custom Length Available

- Color

- Silver

- Installation

- On-site welding

- Package Type

- Export-worthy wooden cases / Cartons

- Hardness

- HRB 217 (for 304/316)

- Grades Available

- 304, 304L, 316, 316L, 321, 347, Duplex, Super Duplex

- Usage

- Oil, Gas, Petrochemical, Power Plants, Refineries

- Temperature Range

- -196C to 600C

- Weight

- Depends on Size and Sch

- Corrosion Resistance

- Excellent

- Testing

- Hydrostatic, PMI, Radiographic, Ultrasonic

- Pressure Rating

- Class 150 to 2500

Stainless Steel Sweepolet Trade Information

- Minimum Order Quantity

- 100 Pieces

- Delivery Time

- 10-15 Days

About Stainless Steel Sweepolet

Superior Design for Critical Applications

The Stainless Steel Sweepolet is meticulously designed for pipe branch connections across vital sectors-oil, gas, petrochemical, refineries, and power plants. Offering excellent corrosion resistance and a temperature tolerance from -196C to 600C, it guarantees leak-free installation with elongated 45 sweep. Advantageously, its customized length, wide thickness, and diameter options ensure a perfect fit. Polished surfaces, passivated treatment, and strict hardness and tolerance standards make it the preferred choice for high-integrity systems worldwide.

Sample Availability and Reliable Delivery with Secure Packaging

Experience our sample Stainless Steel Sweepolet at the lowest price in the domestic market-handed over quickly to your project site for inspection and approval. Each product is shipped in export-worthy wooden cases or sturdy cartons, capped with protectors to prevent transit damage. The streamlined process ensures prompt dispatch so you receive your order within your required timeframe. Trust our packaging and logistics for reliable, timely delivery in India and abroad.

FAQ's of Stainless Steel Sweepolet:

Q: How is the Stainless Steel Sweepolet installed at project sites?

A: The Stainless Steel Sweepolet is installed using on-site welding, ensuring a secure and reliable connection to piping systems as a branch fitting.Q: What testing processes are used to guarantee quality?

A: Each Sweepolet undergoes hydrostatic, PMI, radiographic, and ultrasonic testing, ensuring structural integrity and adherence to international quality standards.Q: When should I use a Sweepolet for my piping system?

A: Sweepolets are ideal for making branch connections in high-pressure, high-temperature environments such as oil, gas, petrochemical, refineries, and power plants.Q: Where can I order Sweepolets with customized dimensions?

A: You can order Sweepolets directly from our manufacturing facilities in India, specifying custom lengths, thicknesses, and diameters to suit your project requirements.Q: What are the benefits of the stainless steel grades provided?

A: Using grades like 304, 316, Duplex, and Super Duplex ensures excellent corrosion resistance, superior strength, and enhanced durability in challenging operating conditions.Q: How are Sweepolets packaged to prevent damage during delivery?

A: Sweepolets are packed in export-worthy wooden cases or cartons, fitted with plastic end caps and supported with protective packaging for safe shipment.

Price 500 INR/ Piece

- Minimum Order Quantity

- 100 Pieces

- Delivery Time

- 10-15 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Fitting Products Category

Bulkhead Male Connector

Price 150 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Other, Hydraulic and Pneumatic Systems

Technique : Other, CNC Machined

Length : Varies (20 mm to 100 mm)

Alloy or Not : Other, Not Alloy

Stainless Steel Sms Unions

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Other, Dairy, Food, Beverage, Pharmaceutical Industries

Technique : Other, Forged / Machined

Length : Standard and Custom

Alloy or Not : Other, Alloy

Long and Short End Stub

Price 250 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Other, Pipeline, Construction, Oil & Gas, Water Supply

Technique : Other, Hot Rolled, Cold Drawn

Length : Standard 6 Meter, Custom

Alloy or Not : Other, Not Alloy

GST : 27AAPPS5635Q1ZM

|

PRAGATI METAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese