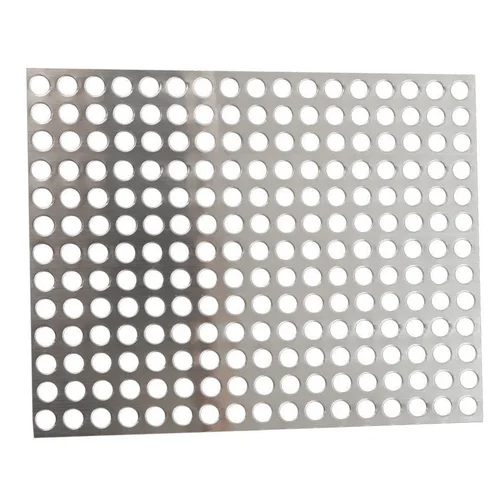

Stainless Steel Perforated Sheets

Stainless Steel Perforated Sheets Specification

- Coating Type

- Uncoated / Electro-Polished

- Size

- Standard and Customizable

- Product Form

- Perforated Sheet

- Tensile Strength

- 515-620 MPa for 304

- Corrosion Resistant

- Yes

- Material Composition %

- Cr 18-20%, Ni 8-10% (304), Cr 16-18%, Ni 10-14% (316)

- Hardness

- HRB 80-90 (Brinell 170-220)

- Recyclable

- Yes

- Heat Resistance

- Yes

- Diameter

- Hole Diameter: 0.5mm - 20mm

- Product Name

- Stainless Steel Perforated Sheet

- Steel Type

- Stainless Steel

- Steel Product Type

- Sheet

- Grade

- 304, 316

- Thickness

- 0.5 mm to 5 mm

- Shape

- Rectangular Sheet with Round/Slot/Custom Holes

- Steel Standard

- ASTM A240 / AISI

- Surface

- Polished, Matte, Brushed

- Composition

- Iron, Chromium, Nickel (depending on grade)

- Application

- Industrial, Architectural, Filters, Machinery Guarding, Ventilation

- Dimension (L*W*H)

- Standard: 8ft x 4ft, Custom sizes available

- Weight

- Varies with thickness and size (typically 5-50 kg per sheet)

- Color

- Silver

- Material Grade

- SS 304, SS 316

- Finish Type

- Mill Finish, 2B, BA Finish

- Usage

- Screening, Sieving, Acoustic Panels, Decor, Ventilation

- Max Width

- Up to 1500 mm

- Manufacturing Technology

- CNC Punching, Laser Cutting

- Hole Pattern

- Round, Square, Slotted, Hexagonal

- Surface Treatment

- Oil Coated for rust prevention, Dry or Cleaned

- MOQ

- As per customer demand

- Open Area Percentage

- 10% - 60% depending on pattern

- Max Length

- Up to 4000 mm

- Packaging Type

- Wooden Pallet, Plastic Wrapped, as required

- Edge Type

- Sheared, Smooth, or Untrimmed

Stainless Steel Perforated Sheets Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 10-15 Days

About Stainless Steel Perforated Sheets

Usage and Application Guidelines for Stainless Steel Perforated Sheets

For best results, position the sheet according to the airflow, screening or decorative needs. Select proper fastening-bolting, welding, or slot-mounting-based on your installation method. Ideal for industrial filters, acoustic barriers, facade claddings, machinery guarding, and ventilation ducts, these sheets deliver exceptional performance across diverse environments. Prioritize regular checks for maintenance and use appropriate surface treatment-oil coated for rust prevention or dry/cleaned for indoor applications.

Packaging, Delivery, and Payment for Perforated Sheet Orders

Shipped goods are securely delivered using wooden pallets or plastic wrap, tailored to minimize freight damage and ensure immaculate arrival. We serve the main domestic market across India with prompt and reliable delivery. Freight charges may vary based on destination and order size. Payment terms are convenient, and can be discussed to suit your procurement needs. Our experienced export and logistic channels guarantee safe, orderly, and timely shipment of stainless steel perforated sheets.

FAQ's of Stainless Steel Perforated Sheets:

Q: How do I choose the right hole pattern and open area percentage for my project?

A: Determine your application-ventilation, filtration, or decoration-to select from round, square, slotted, or hexagonal patterns. The open area percentage (10%-60%) affects airflow, strength, and visibility, so consult our experts for optimal configuration.Q: What is the process for ordering customized perforated sheets?

A: You can request sheets in standard 8ft x 4ft size or specify custom dimensions, hole diameter (0.5mm-20mm), and edge type. Share your requirements with us, and our team will provide tailored solutions using laser cutting or CNC punching technology.Q: When can I expect my stainless steel perforated sheets to be delivered?

A: Delivery times depend on the order quantity and customization. Standard products are dispatched quickly, while custom orders may require additional processing time. You will receive a timeline when you place your order.Q: Where are these stainless steel perforated sheets commonly used?

A: They are widely deployed in industrial, architectural, and filtration sectors. Applications include machinery guarding, acoustic panels, facade cladding, sieving, ventilation grilles, and decorative screens.Q: What are the main benefits of using SS 304 or SS 316 perforated sheets?

A: SS 304 and SS 316 offer excellent corrosion resistance, strength, and heat tolerance (up to 925C for SS 316). These qualities ensure durability and longevity, making your installations both high-performing and cost-effective.Q: How are the stainless steel perforated sheets packaged for delivery?

A: Sheets are securely packaged using wooden pallets and plastic wrappings to shield them during transit and preserve their immaculate surface finish.

Price 240 INR/ Kilograms

- Minimum Order Quantity

- 100 Kilograms

- Delivery Time

- 10-15 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

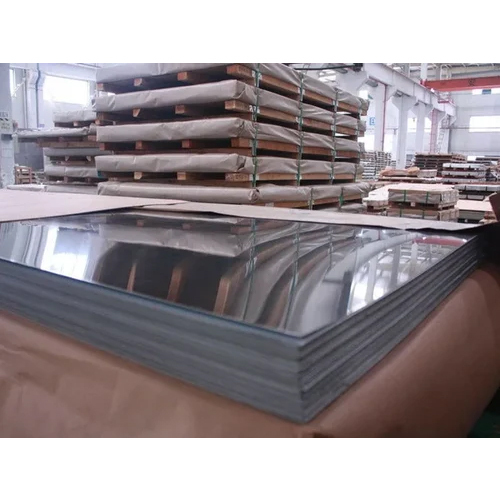

More Products in Stainless Steel Sheet Category

Stainless Steel 202 Coils

Price 140 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Steel Product Type : Other, Coil

Grade : 202

Shape : Other, Coil

Steel Standard : Other, ASTM A240 / A240M

Stainless Steel Bright Bar

Price 200 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Steel Product Type : Other, Bar

Grade : 201, 202, 304, 304L, 316, 316L, 410, 420, 430 or as specified

Shape : Other, Round, Square, Hexagonal, Flat

Steel Standard : Other, ASTM, JIS, DIN, EN, GB, IS

430 Stainless Steel Sheet

Price 80 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Steel Product Type : Other, Sheet

Grade : 430

Shape : Other, Rectangular/Sheet

Steel Standard : Other, ASTM A240 / JIS G4305 / EN 10088 / DIN 17441

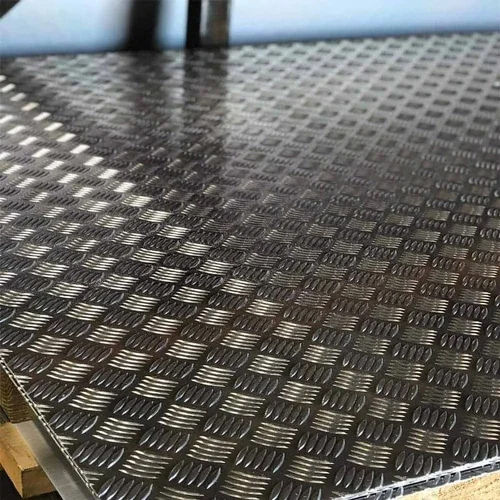

Stainless Steel Chequered Plates

Price 240 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Steel Product Type : Other, Chequered / Tread Plate

Grade : 304, 316, 304L, 316L or as specified

Shape : Other, Rectangular/Sheet

Steel Standard : Other, ASTM A240, JIS G4304, DIN EN 10088, IS 6911

GST : 27AAPPS5635Q1ZM

|

PRAGATI METAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese